Project Make Launched

Background

First some background on what is normally required to create a garment sample.

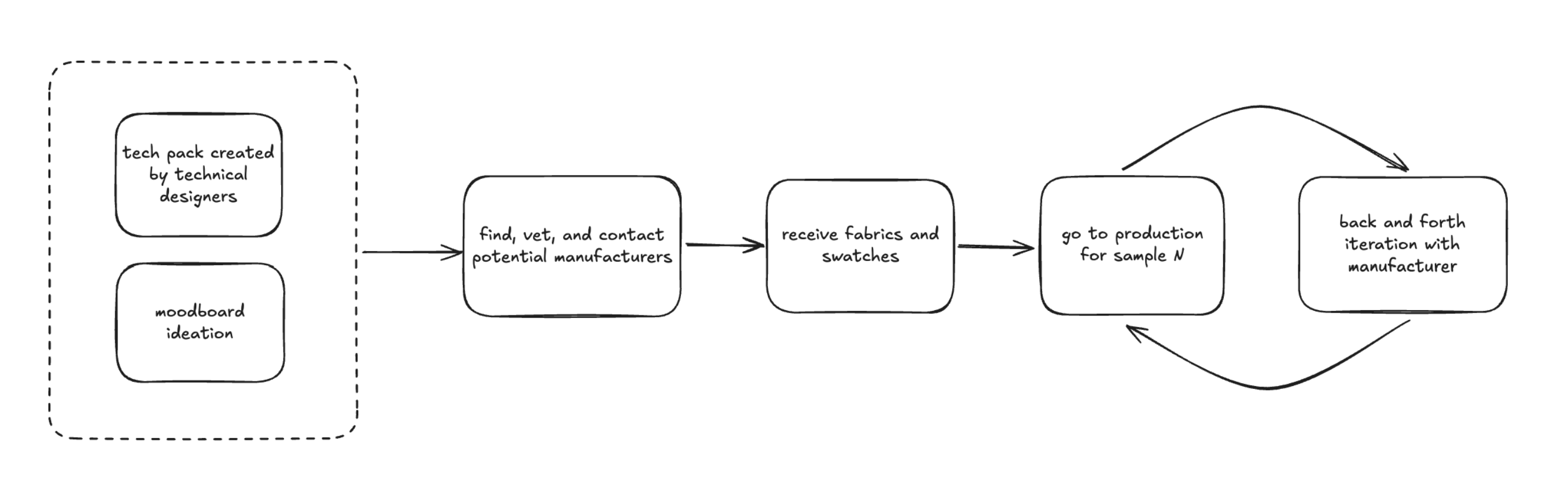

The creative director or designer of the brand will ideate through mood boards and come up with an initial concept. The garment design is then translated into a tech pack, which is a document that contains key manufacturing instructions like construction details, grading specs, print placements, etc.

Next, reliable manufacturers with the capability to produce the garment need to be identified, vetted, and contacted. The most reliable way of doing this is through referrals. Other common methods include scouring websites such as Alibaba, 1688.com, ImportYeti, MakersRow, etc.

In the vetting process, vendors might send fabric and colour swatches for the garment and discuss any questions about construction. Once they have the green light, and receive payment, the first sample will go into production.

During the manufacturing process, many brands are ghosted or faced with inconsistent communications from their communication. Some brands that have spent over a year trying to find a solid manufacturing partner.

Once the first sample is produced, the manufacturer will send some updates and images for additional feedback and approval. The approved sample will be shipped and await further feedback. Apparel products will usually go through 2-3 iterations before reaching a final form called a salesman sample, which will be ordered in bulk and ready to sell to customers.

Technical setup

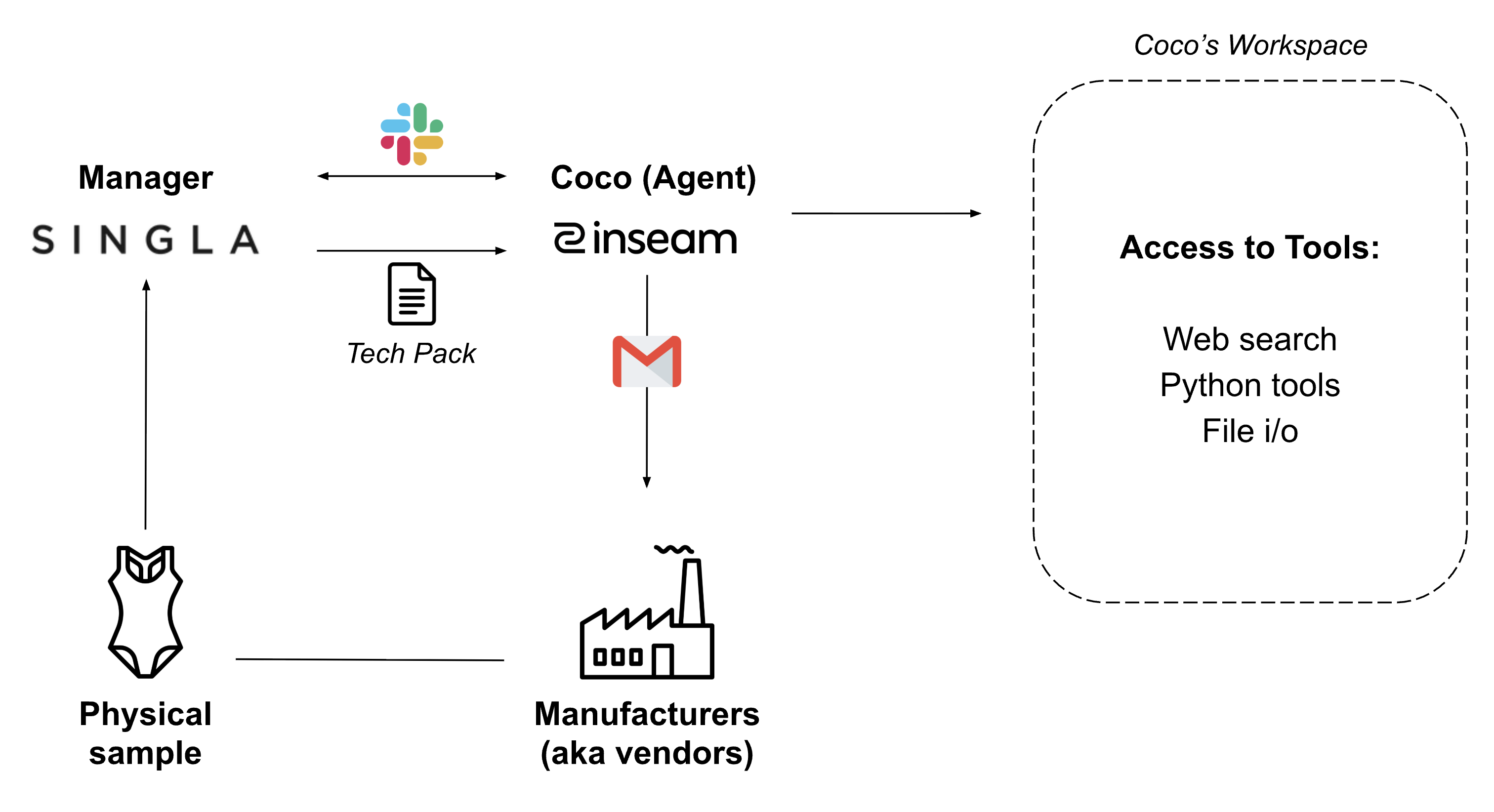

The goal of our agent, Coco, is to streamline the process of vendor sourcing, communications, and coordination. We want to eliminate the majority of administrative and process work, and provide operators with an autonomous production manager to support their organization.

We've partnered with Singla Intimates, who will act as the human manager to Coco. We communicate with Coco via Slack, the same way we'd communicate with any other team member.

Coco has its own Gmail account, which it will use to communicate with vendors and any external parties. Coco can search through email history, read attachments, and respond professionally to any email.

Coco also has access to its own (growing) set of tools such as web search, creating python scripts, general file input/output, etc.

This is the high level architecture, and it is subject to change as we learn and improve Coco's behavior.

Future

On one hand, we are trying to see if this will solve a business challenge. From a technical lens this is also an exploration of agent harnessing techniques in a real-world high-stakes environment. This is a deeply underexplored field, and we will see much more developments made in the coming year.

Coco is operational and ready to start working, so we're going to be putting it to the test: finding manufacturers, negotiating samples, and navigating the messy reality of garment production.

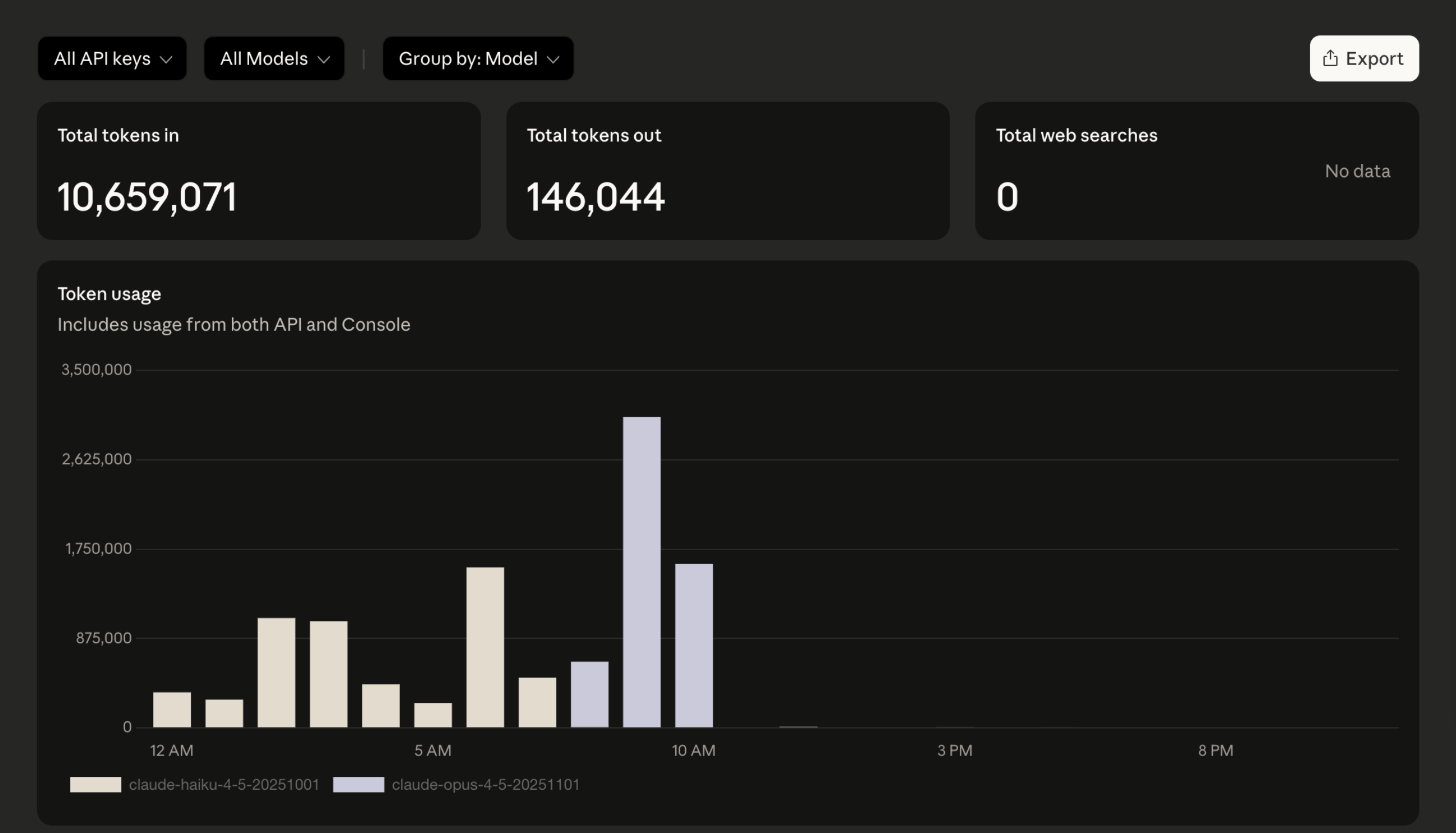

Coco token tracker

To finish off, here is the daily token tracker. Coco was hard at work consuming ~11 million tokens, costing us about $32: